Why Is Hollow Board a Game Changer in Modern Packaging and Construction?

2024-12-03

Hollow boards, often referred to as twin-wall or fluted boards, have become a popular choice across various industries due to their unique properties and wide range of applications. But what exactly is a hollow board, and why is it being adopted in so many sectors, from packaging to construction? In this blog, we will explore the advantages of hollow boards, their uses, and why they are considered a game changer in modern industries.

What is a Hollow Board?

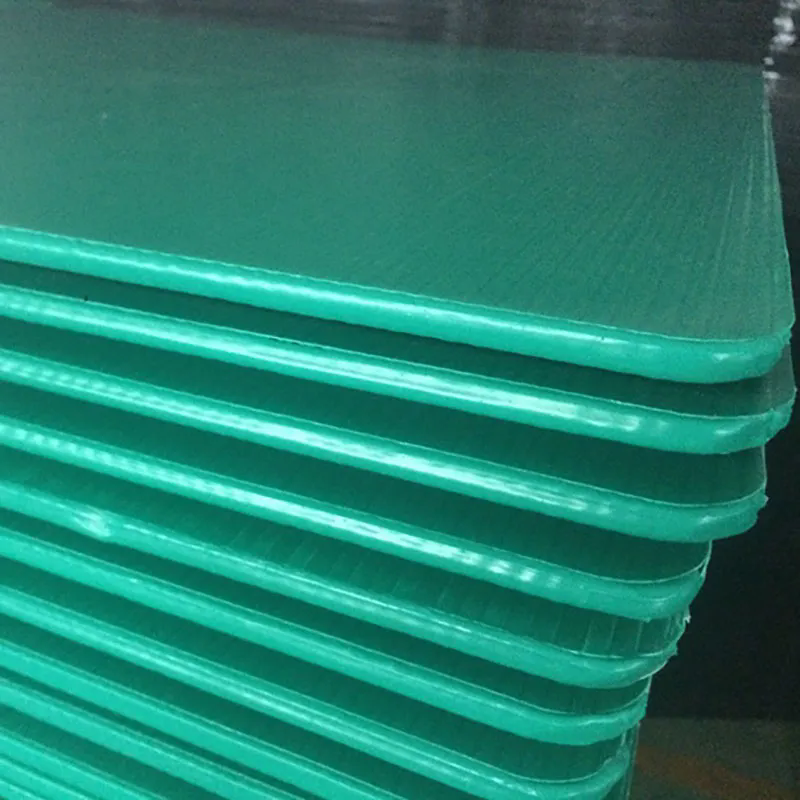

A hollow board is a lightweight yet durable material typically made from polyethylene or polypropylene. It consists of two flat layers with an inner structure resembling a honeycomb or fluted design, creating hollow spaces between the layers. These gaps offer several benefits, including reduced weight and improved strength. The structure also makes hollow boards resistant to bending, making them ideal for numerous applications.

Why Are Hollow Boards So Popular?

1. Lightweight and Strong

One of the standout features of hollow boards is their combination of strength and low weight. Thanks to their honeycomb-like internal structure, hollow boards can maintain excellent strength while being significantly lighter than solid plastic or cardboard alternatives. This makes them ideal for applications that require a balance between durability and ease of handling, such as packaging, signage, and temporary construction barriers.

2. Cost-Effective

Hollow boards are also highly cost-effective. Their production process is less resource-intensive compared to many solid materials, and their lightweight nature reduces transportation costs. This makes them a great choice for industries looking to lower expenses without compromising on the quality of the final product. Whether for shipping, construction, or storage, hollow boards provide an affordable alternative to more expensive materials.

3. Eco-Friendly and Recyclable

As concerns about sustainability grow, industries are increasingly turning to eco-friendly materials. Hollow boards are often made from recyclable plastics, offering a more sustainable solution compared to other forms of packaging and construction materials. Not only are they reusable, but they are also lightweight, which further reduces transportation costs and environmental impact. Many hollow board products are fully recyclable, making them an attractive choice for businesses striving to meet eco-friendly standards.

4. Impact-Resistant

Hollow boards are impact-resistant due to their structure, making them ideal for use in environments where the material may be subject to rough handling or heavy use. For instance, hollow boards are often used in packaging fragile items, as they provide cushioning and protection during shipping and storage. Their ability to absorb shocks and resist dents means they can withstand more pressure than many solid materials, ensuring products inside remain intact.

5. Water and Weather Resistance

Another benefit of hollow boards is their water and weather resistance. The materials used in manufacturing hollow boards, typically polypropylene and polyethylene, are highly resistant to moisture, chemicals, and extreme weather conditions. This makes hollow boards suitable for outdoor use, whether in signage, construction barriers, or storage solutions. They are less likely to degrade or weaken when exposed to rain, snow, or high humidity compared to other materials like cardboard or wood.

What Are the Common Uses of Hollow Boards?

1. Packaging and Shipping

Hollow boards are commonly used in packaging applications due to their strength, lightweight nature, and protection capabilities. They are ideal for packaging products that need to be protected during transit, as they can absorb shocks and prevent damage. Hollow boards are used in crates, boxes, pallets, and dividers, ensuring that products remain safe during storage and shipping.

2. Signage and Advertising

In the signage industry, hollow boards have become a popular choice for making outdoor signs, displays, and advertisements. Their resistance to weather and water damage, combined with their lightweight properties, makes them perfect for creating durable and long-lasting signs for retail, real estate, and event advertising. They can easily be cut, printed on, and customized to fit a variety of needs.

3. Construction and Building Materials

In construction, hollow boards are used for a range of temporary and semi-permanent applications. Their durability, resistance to moisture, and ease of handling make them ideal for use as barriers, partition walls, and formwork. They are commonly used in building scaffolding, wall panels, and flooring materials due to their ability to withstand heavy loads and harsh conditions.

4. Storage Solutions

Hollow boards are also widely used in storage applications. Their strength, lightweight nature, and resistance to moisture make them perfect for organizing materials in warehouses or factories. They are often used for creating custom shelving units, containers, and bins to store various goods. Because they are easy to stack and arrange, hollow boards offer a practical solution for improving storage efficiency.

5. Agriculture

In agriculture, hollow boards have been used in creating protective barriers for crops and plants. Their lightweight structure allows for easy installation and movement in agricultural settings, and their resistance to weather conditions ensures they last longer than traditional materials. They can be used to construct greenhouses, irrigation barriers, and plant separators, making them a versatile option in modern farming practices.

How Are Hollow Boards Manufactured?

The manufacturing process of hollow boards typically involves extrusion. Polypropylene or polyethylene plastic is melted and extruded into a thin sheet, which is then formed into two outer layers with an internal fluted structure. The sheets are cooled, cut to size, and often laminated or printed based on their intended use. This process is highly efficient and allows for the large-scale production of hollow boards in a variety of shapes and sizes.

Conclusion

Hollow boards are revolutionizing a variety of industries due to their combination of strength, lightweight design, cost-effectiveness, and eco-friendliness. Whether used for packaging, construction, signage, or agricultural purposes, they offer an affordable, durable, and sustainable solution that meets the demands of modern applications. As industries continue to seek out materials that balance performance with environmental responsibility, hollow boards are poised to play an even greater role in the future.