Why Is a Mechanical Bar Screen Essential for Wastewater Treatment?

2025-06-25

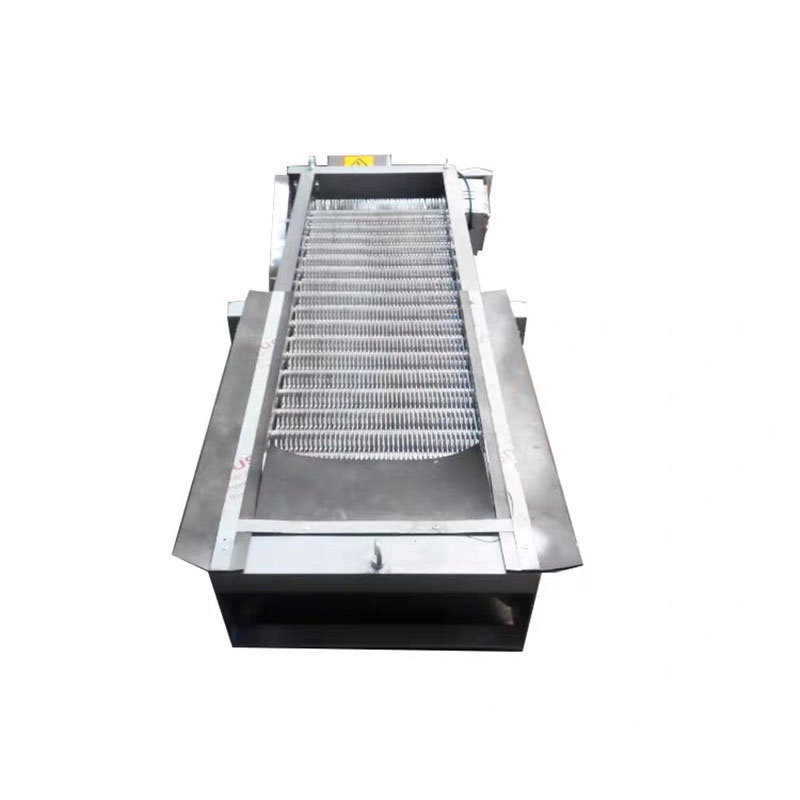

In any efficient wastewater treatment system, preliminary screening plays a critical role. One of the most reliable and widely used solutions for removing large solids from incoming wastewater is the Mechanical Bar Screen. Engineered for durability and continuous operation, this device helps protect downstream equipment and improve the overall treatment process.

What Is a Mechanical Bar Screen?

A mechanical bar screen is a solid-liquid separation device used in the pre-treatment stage of wastewater management systems. It consists of a series of evenly spaced bars (the screen) and a mechanical cleaning mechanism that automatically removes debris such as:

Rags

Plastics

Leaves

Bottles

Paper

Other solid waste

The screen prevents large items from entering and damaging pumps, pipelines, or fine filtration systems further downstream.

How Does It Work?

The operation of a mechanical bar screen typically follows these steps:

1. Wastewater Flow: Raw wastewater flows through the screen chamber.

2. Debris Capture: Solid materials are trapped on the front face of the bars.

3. Mechanical Cleaning: A rake or cleaning comb, driven by a chain or motor, moves upward to lift the trapped debris.

4. Discharge: Collected waste is conveyed to a container, conveyor belt, or washing press.

5. Continuous Operation: The system repeats this process automatically at preset intervals or based on water level sensors.

What Are the Key Benefits?

Mechanical bar screens offer several operational advantages:

Automatic cleaning: Reduces labor and maintenance effort.

High efficiency: Removes large solids effectively and continuously.

Protection: Prevents clogs and damage in downstream systems.

Durability: Made from corrosion-resistant stainless steel or high-strength materials.

Customizable: Available in various bar spacings, widths, and lengths to fit specific channel sizes.

Where Are They Used?

Mechanical bar screens are commonly used in:

Municipal wastewater treatment plants

Industrial water treatment systems

Stormwater drainage facilities

Slaughterhouses and food processing plants

Pumping stations and sewage lift stations

In any application where solid waste removal is required before further processing, a bar screen proves vital.

What to Consider When Choosing a Bar Screen?

When selecting a mechanical bar screen, consider the following factors:

Flow rate: Ensure the screen size matches the volume of water being treated.

Bar spacing: Typically ranges from 3 mm to 50 mm depending on application.

Material of construction: Stainless steel is recommended for long-term use.

Cleaning mechanism: Choose between chain-driven, belt-driven, or hydraulic systems.

Automation level: Opt for sensor-based or time-controlled operation for efficiency.

Final Thoughts

The mechanical bar screen may seem simple, but it is one of the most crucial components in any wastewater treatment system. By efficiently removing coarse debris early in the process, it protects infrastructure, reduces downtime, and ensures smoother downstream operations. A well-designed bar screen is an investment in reliability, performance, and operational safety.