Here's a breakdown of key points about CFRTP sheets

2024-03-21

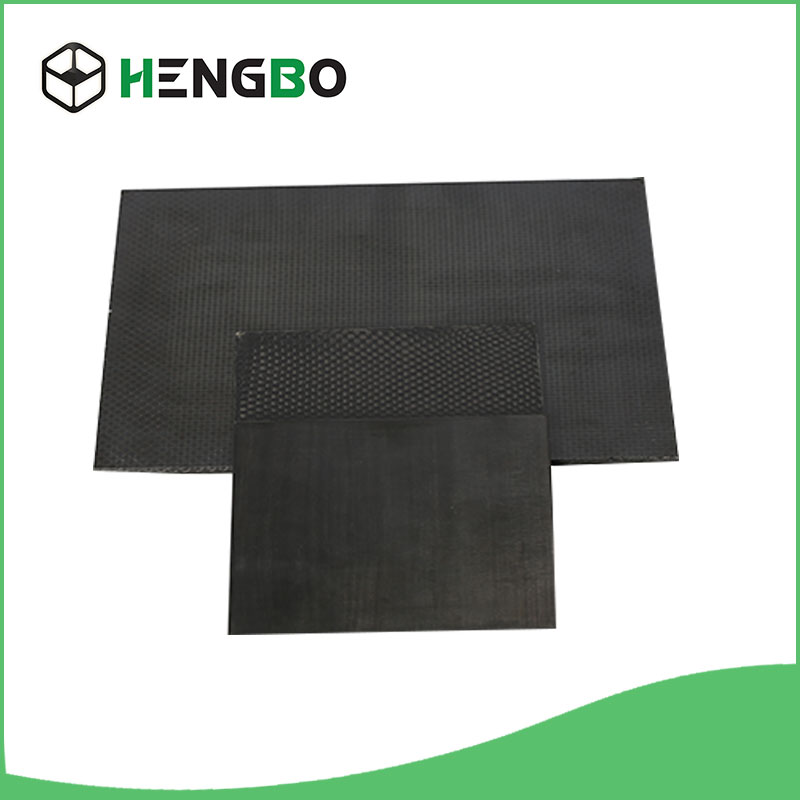

CFRTP stands for Carbon Fiber Reinforced Thermoplastic. A CFRTP sheet is a composite material sheet made by combining carbon fibers with a thermoplastic polymer matrix.

Here's a breakdown of key points about CFRTP sheets:

1. Composition: CFRTP sheets are composed of high-strength carbon fibers embedded within a thermoplastic polymer matrix. The carbon fibers provide excellent tensile strength, stiffness, and lightweight properties, while the thermoplastic matrix provides toughness, flexibility, and ease of processing.

2. Manufacturing Process: CFRTP sheets are typically produced using techniques such as lay-up, compression molding, or continuous fiber processing. In the lay-up process, carbon fiber fabric or pre-impregnated tapes are arranged in layers and then infused or coated with the thermoplastic resin. Compression molding involves heating and compressing the fiber-resin composite to shape it into a sheet form. Continuous fiber processing methods involve pulling carbon fibers through a bath of molten thermoplastic resin to create a continuous sheet.

3. Properties: CFRTP sheets offer exceptional mechanical properties, including high strength-to-weight ratio, stiffness, and impact resistance. They are also resistant to corrosion, chemicals, and fatigue. The specific properties of CFRTP sheets can be tailored by adjusting the type of carbon fibers, the polymer matrix, and the manufacturing process parameters.

4. Applications: CFRTP sheets find applications in various industries such as aerospace, automotive, sports equipment, marine, and industrial sectors. They are used to manufacture lightweight structural components, panels, body parts, interior components, and other parts requiring high strength and low weight.

5. Advantages: CFRTP sheets offer several advantages over traditional materials such as metals or thermoset composites. These include reduced weight, improved fuel efficiency, enhanced durability, design flexibility, and ease of recyclability due to the thermoplastic matrix.

6. Challenges: Despite their numerous advantages, CFRTP sheets also present some challenges, including higher material costs compared to conventional materials, processing complexities, and limited availability of high-performance thermoplastic resins suitable for use with carbon fibers.

Overall, CFRTP sheets represent a promising class of materials with a wide range of potential applications, particularly in industries where lightweight and high-performance materials are critical for achieving performance targets and efficiency goals.