Functions and Features of Pneumatic Air Hoses

2024-06-12

A pneumatic air hose is a flexible tube used to convey compressed air from a compressor or other air source to pneumatic tools, equipment, or machinery. These hoses are specifically designed to withstand the high pressure and airflow associated with pneumatic systems. Here's an overview of pneumatic air hoses:

Functions and Features

1. Conveying Compressed Air:

- Pneumatic air hoses transport compressed air from the air compressor to pneumatic tools and equipment, such as pneumatic drills, nail guns, impact wrenches, spray guns, and air-powered machinery.

2. Flexibility and Maneuverability:

- Pneumatic air hoses are flexible and lightweight, allowing for easy handling and maneuverability in various industrial, automotive, construction, and DIY applications.

3. Pressure Resistance:

- Pneumatic air hoses are designed to withstand high pressures typically ranging from 150 to 300 PSI (pounds per square inch), ensuring reliable and efficient operation of pneumatic systems.

4. Durability and Longevity:

- Pneumatic air hoses are constructed from durable materials such as rubber, PVC (polyvinyl chloride), polyurethane, or hybrid blends, which provide resistance to abrasion, weathering, oil, and chemicals, ensuring long-lasting performance in harsh environments.

5. Compatibility:

- Pneumatic air hoses come in various sizes, diameters, and lengths to accommodate different pneumatic tools and equipment, as well as different air compressor setups and configurations.

6. Safety:

- Pneumatic air hoses may feature reinforced braided or spiral construction to prevent kinking, twisting, or collapsing under pressure, reducing the risk of hose failure and workplace accidents.

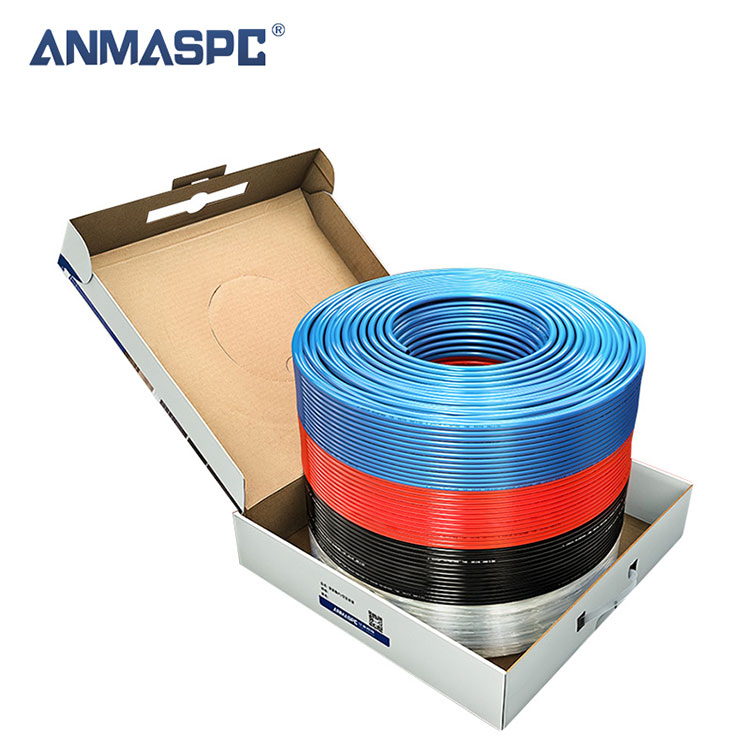

7. Color-Coding:

- Some pneumatic air hoses are color-coded for easy identification and differentiation of different hose sizes, types, or applications, enhancing safety and efficiency in pneumatic systems.

Types of Pneumatic Air Hoses

1. Rubber Air Hoses:

- Rubber air hoses are flexible and durable, making them suitable for a wide range of pneumatic applications. They offer excellent abrasion resistance and flexibility, even in cold weather conditions.

2. PVC Air Hoses:

- PVC air hoses are lightweight and economical, making them ideal for general-purpose pneumatic applications. They offer good flexibility and chemical resistance but may not withstand extreme temperatures or harsh environments as well as rubber hoses.

3. Polyurethane Air Hoses:

- Polyurethane air hoses combine the flexibility of rubber hoses with the abrasion resistance of PVC hoses. They are lightweight, durable, and resistant to kinking and twisting, making them suitable for heavy-duty pneumatic applications.

4. Hybrid Air Hoses:

- Hybrid air hoses are constructed from a blend of materials, such as rubber and PVC or rubber and polyurethane, to provide a balance of flexibility, durability, and cost-effectiveness for pneumatic applications.

Considerations for Selection and Usage

1. Pressure Rating:

- Select a pneumatic air hose with a pressure rating that meets or exceeds the maximum pressure requirements of your pneumatic tools, equipment, or air compressor system.

2. Temperature Range:

- Consider the temperature range of the environment where the pneumatic air hose will be used and choose a hose material that can withstand the temperature extremes encountered in that environment.

3. Hose Size and Length:

- Choose the appropriate hose size (inner diameter) and length to ensure sufficient airflow and flexibility for your pneumatic application, taking into account the distance between the air compressor and the pneumatic tool or equipment.

4. End Fittings:

- Ensure that the pneumatic air hose is equipped with compatible end fittings, such as quick-connect couplers or barbed fittings, for easy connection to pneumatic tools, equipment, or air compressor outlets.

5. Safety Precautions:

- Inspect pneumatic air hoses regularly for signs of wear, damage, or deterioration, and replace any damaged hoses immediately to prevent accidents or injuries caused by hose failure.

Conclusion

Pneumatic air hoses are essential components of pneumatic systems, providing a reliable and efficient means of conveying compressed air to pneumatic tools, equipment, and machinery. By selecting the appropriate type, size, and material of pneumatic air hose and following proper installation and maintenance practices, users can ensure safe and efficient operation of their pneumatic systems in various industrial, commercial, and residential applications.