Function and Purpose of Round Condenser Tube

2024-07-12

A round condenser tube refers to a type of tubing used in condenser units, particularly in various industrial and mechanical applications where efficient heat transfer and condensation are necessary. Here are the key aspects and functions of round condenser tubes:

Function and Purpose

1. Heat Transfer

- Round condenser tubes are designed to facilitate the transfer of heat from a hot fluid (such as refrigerant vapor or steam) to a cooler fluid (usually air or water).

- Used in condenser units to convert vapor into liquid through cooling and condensation processes.

2. Condensation

- The tube's design allows for the efficient condensation of gases or vapors into liquids, typically by maintaining a cool temperature through contact with a coolant or ambient air.

Construction and Features

1. Material

- Constructed from materials such as copper, aluminum, stainless steel, or alloys suited for heat transfer and corrosion resistance.

- Material selection depends on the specific application requirements, environmental conditions, and fluid properties.

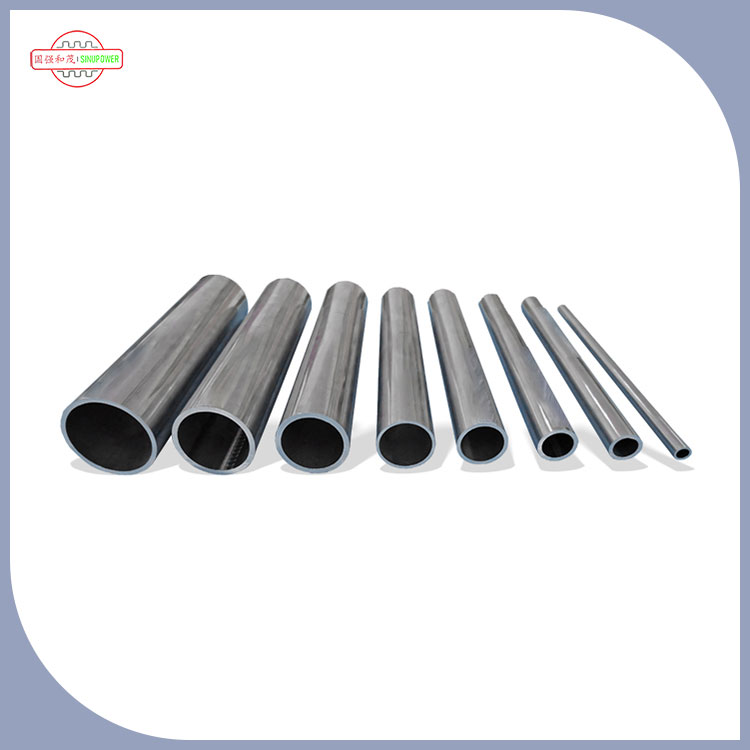

2. Size and Dimensions

- Available in various sizes and diameters to accommodate different flow rates, pressure requirements, and heat exchange capacities.

- Standard sizes can range from small diameters used in household appliances to larger diameters for industrial-scale applications.

3. Design

- Typically designed with smooth surfaces to facilitate fluid flow and minimize resistance.

- May include internal enhancements such as fins or rifling to increase surface area and enhance heat transfer efficiency.

4. Compatibility

- Designed to be compatible with different types of condenser units and systems, including air-cooled condensers, water-cooled condensers, and heat exchangers.

- Configurations can vary from straight tubes to coiled or spiral designs depending on space and efficiency requirements.

Applications

- HVAC Systems: Used in air conditioning units, refrigeration systems, and heat pumps for cooling and refrigerant condensation.

- Power Generation: Found in power plant condensers for converting steam into liquid water in steam turbine cycles.

- Industrial Processes: Utilized in various industrial applications requiring efficient heat exchange and condensation, such as chemical processing, oil refining, and food production.

Considerations

- Heat Transfer Efficiency: Choose tube materials and designs that optimize heat transfer efficiency for specific operating conditions.

- Corrosion Resistance: Select materials resistant to corrosion and erosion, especially in environments with aggressive fluids or outdoor exposure.

- Maintenance: Regular inspection and maintenance to ensure optimal performance and prevent fouling or scaling that can reduce efficiency.

Summary

Round condenser tubes play a critical role in facilitating heat transfer and condensation processes in a wide range of industrial and mechanical applications. Their design, material composition, and efficiency are crucial factors in achieving effective cooling, refrigeration, and heat exchange operations across various industries.