Detailed description of Black OPP Metalized film

2024-06-28

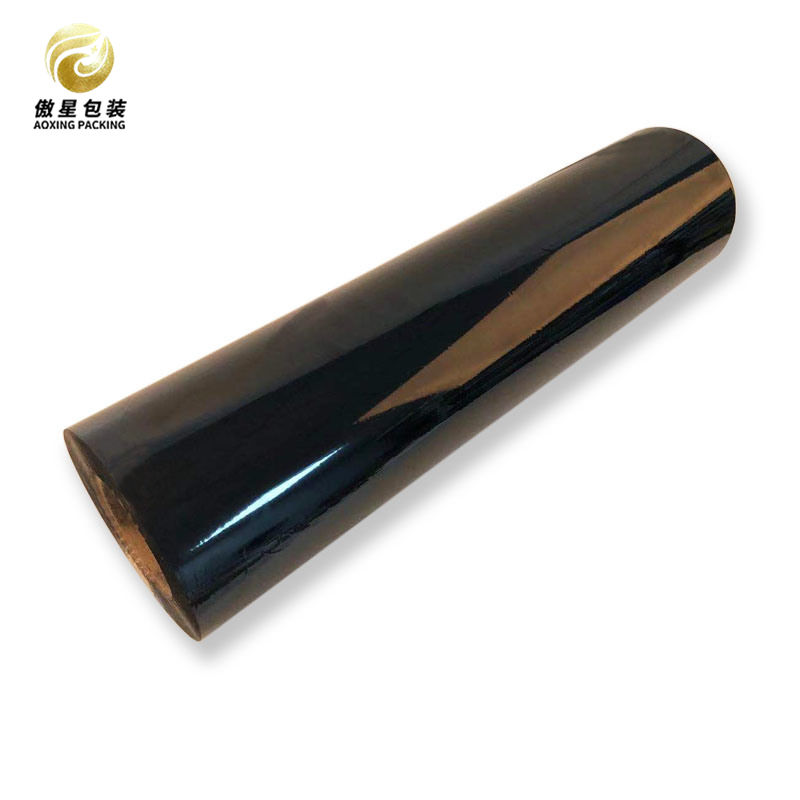

Black OPP (Oriented Polypropylene) Metalized film is a type of packaging material known for its unique properties and applications:

1. Material Composition: It is typically made from oriented polypropylene, which is a versatile plastic known for its strength, clarity, and resistance to moisture and chemicals.

2. Metalization Process: The film undergoes a metalization process where a thin layer of metal (often aluminum) is deposited onto one side of the OPP film. This metal layer enhances the film's barrier properties, making it impermeable to gases like oxygen and moisture, which helps in preserving the freshness and shelf life of packaged products.

3. Color and Appearance: The metalized side of the film gives it a distinct metallic appearance, usually silver or black, depending on the desired aesthetic or functional properties. Black OPP Metalized film, in particular, has a black color on the metalized side.

4. Applications:

- Packaging: It is widely used in food packaging (snack foods, confectionery, etc.), pharmaceutical packaging, and other consumer goods where product visibility combined with barrier properties is important.

- Printing: The non-metalized side of the film is suitable for high-quality printing, making it ideal for packaging that requires branding, information, or decorative elements.

5. Advantages:

- Barrier Properties: Effective barrier against moisture, oxygen, and other gases.

- Aesthetic Appeal: Metallic finish enhances product presentation and shelf appeal.

- Versatility: Can be used for various packaging formats including pouches, wraps, and labels.

6. Environmental Considerations: OPP films, including metalized variants, are recyclable in many regions, contributing to sustainability efforts in packaging.

Overall, Black OPP Metalized film combines the functional benefits of OPP film with enhanced barrier properties and aesthetic appeal, making it a popular choice in modern packaging solutions.