Aspects associated with IPC module boards

2024-01-15

The term "IPC Module Board" likely refers to an industrial PC (IPC) module board or an embedded computing module designed for industrial applications. IPCs are specialized computers built to withstand the harsh conditions of industrial environments and are commonly used in automation, control systems, and other industrial applications.

Here are some key aspects associated with IPC module boards:

1. Industrial PC (IPC):

- An industrial PC is a computing device designed for use in industrial environments. It is built to handle factors such as temperature variations, dust, vibrations, and other challenges commonly found in manufacturing or control systems.

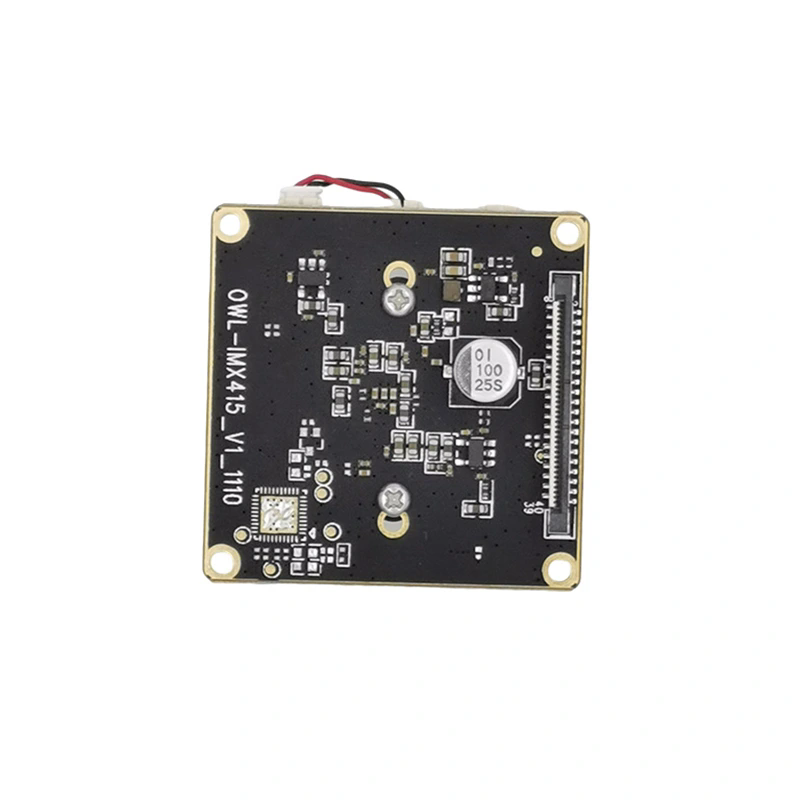

2. IPC Module Board:

- An IPC module board typically refers to the main computing module or core processing unit within an industrial PC system. This module contains the essential components, including the processor, memory, storage, and various interfaces.

3. Embedded Computing Module:

- IPC module boards can be considered a form of embedded computing module. These modules are designed to be integrated into larger industrial systems and may have specific features tailored for industrial applications.

4. Processor:

- IPC module boards are equipped with processors suitable for industrial computing tasks. The choice of processor depends on the performance requirements of the application.

5. Memory and Storage:

- These modules include onboard memory (RAM) and storage (e.g., solid-state drives) to support computing tasks and data storage.

6. I/O Interfaces:

- IPC module boards provide various input and output interfaces to connect with industrial sensors, actuators, and other devices. Common interfaces include digital and analog I/O, serial ports, Ethernet, USB, and fieldbus communication interfaces.

7. Expansion Slots:

- Some IPC module boards may feature expansion slots for adding additional functionality or interfaces. This allows customization to meet specific application requirements.

8. Rugged Design:

- IPC module boards are designed to be rugged and durable, capable of withstanding challenging environmental conditions commonly found in industrial settings.

9. Fanless Operation:

- Many IPC module boards are designed to operate without fans, reducing the risk of dust and debris ingress and minimizing maintenance requirements.

10. Compliance and Certification:

- IPC module boards may adhere to industry standards and certifications relevant to industrial computing, ensuring reliability and compliance with safety and performance requirements.

These IPC module boards are often part of a modular approach in industrial computing systems, allowing for scalability, customization, and ease of maintenance. They may be integrated into larger systems that include displays, user interfaces, and additional peripherals for specific industrial applications such as process control, automation, robotics, and data acquisition.