Innovations in Packaging: The 48 Cavities Edible Oil Pull-tab Lid Mold

2023-10-17

Introduction

Packaging plays a crucial role in preserving the freshness and quality of various food products, including edible oils. Among the many types of packaging options available, pull-tab lids have gained popularity for their convenience and ease of use. These lids provide a tamper-evident seal, ensuring the product's integrity until it reaches the consumer. In recent years, innovations in mold design and manufacturing have led to the development of 48 cavities edible oil pull-tab lid molds, revolutionizing the edible oil packaging industry.

The Significance of Edible Oil Packaging

Edible oils are a staple in kitchens around the world, used for cooking, frying, and salad dressings. Packaging for these oils is essential to maintain their quality, freshness, and nutritional value. Traditional packaging methods often involve screw caps or flip-top lids, but these can be cumbersome and less user-friendly. Pull-tab lids have emerged as a more convenient alternative.

The Rise of Pull-tab Lids

Pull-tab lids have become increasingly popular due to their numerous advantages. These lids are designed to be easy to open and reseal, minimizing the risk of spills and contamination. Additionally, they provide a tamper-evident seal, assuring consumers of the product's safety and quality. These features make pull-tab lids an attractive choice for edible oil packaging.

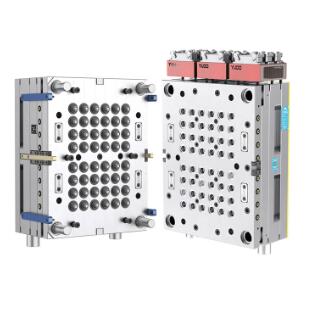

Introducing the 48 Cavities Edible Oil Pull-tab Lid Mold

One of the key developments in the world of pull-tab lids is the 48 cavities edible oil pull-tab lid mold. This mold design is a game-changer for manufacturers looking to enhance production efficiency and reduce costs. Here are some notable aspects of this innovation:

1. Increased Production Capacity: The 48 cavities design allows manufacturers to produce a significantly larger number of lids in a single cycle. This higher production capacity reduces production time and costs, making it a more economical choice for businesses.

2. Precision Engineering: These molds are engineered with precision to ensure uniformity and consistency in lid production. Each lid is manufactured to exact specifications, ensuring a secure fit and reliable sealing.

3. Customization Options: The mold can be customized to produce lids of various sizes and designs, accommodating the specific requirements of different edible oil brands. This versatility allows manufacturers to cater to a wide range of clients.

4. Reduced Material Waste: With its high cavities count and precision engineering, the 48 cavities mold minimizes material waste during production. This not only reduces costs but also aligns with sustainability goals.

5. Enhanced Tamper-Evidence: Pull-tab lids produced using this mold offer superior tamper-evident features, instilling confidence in consumers that the product has not been compromised.

6. User-Friendly Design: These pull-tab lids are designed with user convenience in mind. They are easy to open and reseal, making them an ideal choice for consumers of all ages.

The Impact on the Edible Oil Industry

The introduction of the 48 cavities edible oil pull-tab lid mold has had a significant impact on the edible oil packaging industry. Manufacturers are now better equipped to meet the growing demand for convenient and secure packaging solutions. This innovation not only enhances the consumer experience but also benefits businesses by improving production efficiency and reducing costs.

Conclusion

Innovation in packaging is essential to meet the evolving needs of consumers and businesses alike. The 48 cavities edible oil pull-tab lid mold represents a significant advancement in the packaging of edible oils. Its ability to increase production capacity, reduce material waste, and offer superior tamper-evident features has made it a game-changer in the industry. As consumer preferences continue to shift towards convenience and sustainability, innovations like this mold are likely to shape the future of edible oil packaging.