Gate Valve Engineering Expertise: Non-Rising Stem Solutions by Leading Companies

2025-12-30

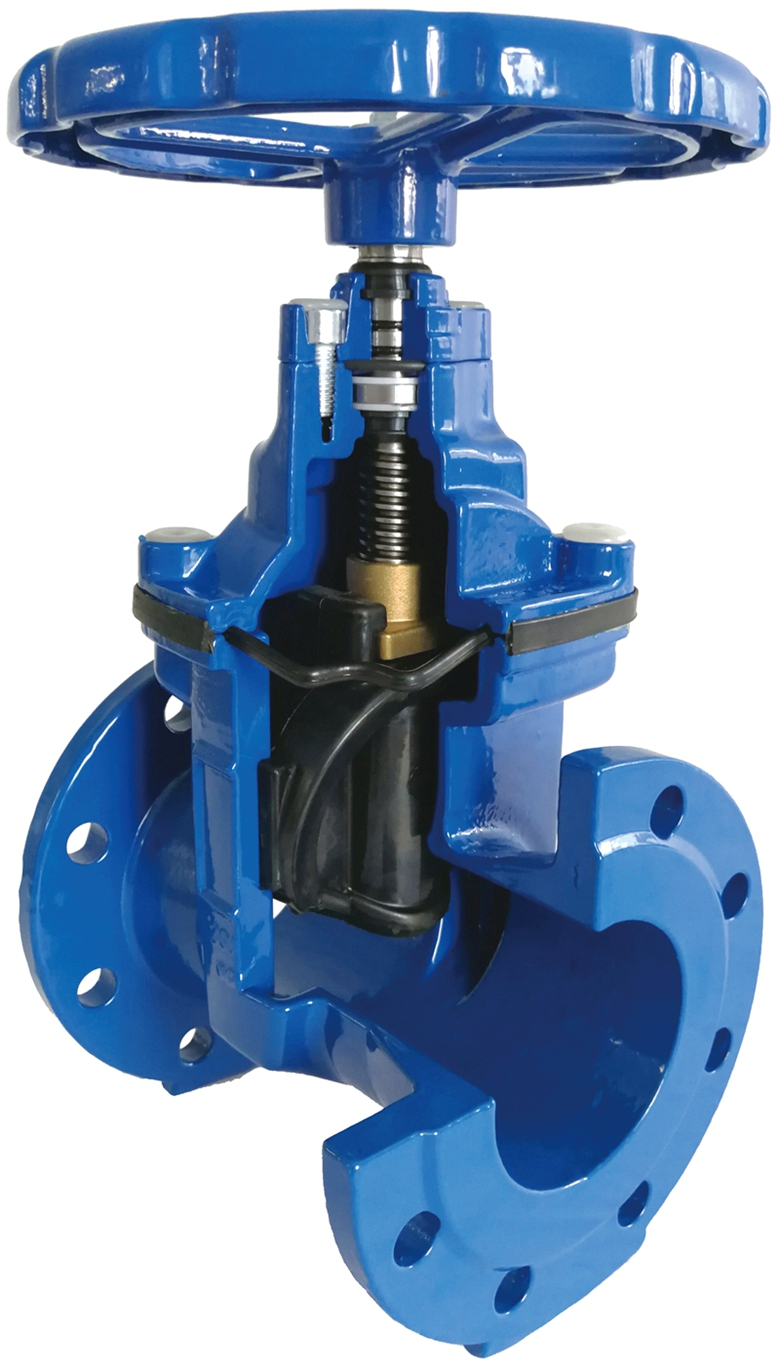

In the world of industrial flow control, gate valves play a pivotal role in managing fluid systems with precision and reliability. Among these, non-rising stem gate valves stand out for their compact design and operational efficiency, making them a preferred choice in space-constrained applications. This blog delves into the engineering expertise behind these innovative solutions, exploring how leading companies are pushing the boundaries of technology and performance. At the forefront of this evolution is DRIFCO, a brand synonymous with cutting-edge valve solutions that prioritize durability and ease of maintenance. Join us as we uncover the key features, benefits, and real-world applications of non-rising stem gate valves, and discover how DRIFCO's expertise is shaping the future of fluid control systems. Whether you're an engineer, a procurement specialist, or simply curious about industrial innovations, this guide will provide valuable insights to fuel your curiosity and enhance your decision-making.

Why Non-Rising Stem Gate Valves Excel in High-Demand Industrial Environments

When efficiency and durability are paramount in industrial operations, non-rising stem gate valves often outperform their counterparts due to their compact design. Unlike rising stem valves that extend outward, the stem in these models remains stationary while the gate moves, reducing the overall height requirement. This feature makes them ideal for confined spaces like pipelines or underground installations, where clearance is limited. Moreover, the non-rising mechanism minimizes external exposure, lowering the risk of corrosion and damage from harsh environments, which helps in maintaining consistent performance over time.

Another key advantage lies in their enhanced safety and reduced maintenance needs. In high-demand settings such as oil refineries or chemical plants, where valves operate under extreme pressure and temperature, non-rising stem designs prevent the stem from protruding, reducing the chance of accidental impact or tampering. This inherently safer configuration means fewer parts are exposed to wear, leading to less frequent inspections and repairs. As a result, these valves contribute to smoother workflow and lower operational costs, making them a reliable choice for industries prioritizing uptime.

Beyond functionality, non-rising stem gate valves offer superior sealing capabilities under varied conditions. The stationary stem allows for tighter packing and better alignment with the gate, ensuring a secure shut-off that prevents leaks even in demanding applications like water treatment or power generation. This reliability, combined with their adaptability to automated systems without requiring extensive modifications, positions them as a versatile solution for modern industrial challenges.

Key Engineering Innovations in Modern Non-Rising Stem Valve Design

One of the standout innovations in modern non-rising stem valve design is the integration of advanced materials such as high-strength alloys and composite materials. These materials greatly enhance corrosion resistance and durability, allowing valves to perform reliably in harsh environments like chemical processing or offshore applications. Unlike traditional designs that might rely on more basic metals, this shift not only extends service life but also reduces maintenance needs, making it a cost-effective choice for industries demanding high performance and safety standards.

Another key advancement lies in improved sealing technologies, particularly with the use of elastomers and engineered plastics. Modern designs often incorporate multiple sealing layers or dynamic seals that adapt under pressure, ensuring tight shutoff and minimizing leakage risks. This innovation addresses common issues in older models, such as stem packing wear or seal degradation over time, thereby boosting operational efficiency and environmental compliance without requiring frequent adjustments or replacements.

Additionally, the adoption of smart, sensor-based monitoring systems has revolutionized non-rising stem valves by enabling real-time data collection and predictive maintenance. Embedded sensors can track parameters like temperature, pressure, and valve position, providing operators with actionable insights to prevent failures and optimize workflows. This connectivity not only enhances safety in critical systems but also aligns with broader industry trends toward automation, setting these valves apart as more intelligent and adaptable solutions for modern industrial setups.

Top Manufacturers Setting the Standard in Durable Valve Solutions

In the competitive landscape of industrial equipment, a select group of manufacturers consistently raises the bar for durable valve solutions, driving innovation and reliability. These industry leaders are renowned for their rigorous quality control processes, extensive material research, and commitment to long-term performance, ensuring that their valves withstand even the harshest operating conditions. By focusing on precision engineering and advanced technologies, they not only enhance safety and efficiency but also set benchmarks that others strive to meet, making them go-to choices for demanding applications worldwide.

What sets these top manufacturers apart is their dedication to customer-centric design and proactive problem-solving, rather than merely following industry norms. They actively engage with end-users across sectors like oil and gas, water treatment, and manufacturing to tailor solutions that address specific challenges, such as corrosion resistance or high-pressure handling. This hands-on approach fosters a culture of continuous improvement, leading to durable valves that minimize downtime and maintenance costs, ultimately delivering superior value and trust in critical systems.

Moreover, their commitment to sustainability and forward-thinking practices adds another layer of distinction, with many investing in eco-friendly materials and energy-efficient designs. By setting these high standards, they not only influence market expectations but also inspire a broader push toward durability and resilience in valve technology, solidifying their role as pioneers in shaping the future of industrial infrastructure.

Essential Considerations for Selecting Industrial Gate Valves with Non-Rising Stems

When choosing industrial gate valves with non-rising stems, it's crucial to evaluate their operational efficiency in confined spaces. Unlike rising-stem valves that require clearance for stem movement, non-rising models keep the stem stationary within the valve body, making them ideal for tight installations where vertical space is limited. This design not only saves physical room but also reduces the risk of damage from external impacts, ensuring smoother maintenance cycles and longer service life in demanding environments like chemical plants or pipeline systems.

Another key factor is the material selection, which directly impacts durability and corrosion resistance. Opt for valves made from robust materials like stainless steel or ductile iron, especially when handling aggressive fluids or high-pressure conditions. Consider the specific application needs—for instance, in marine settings, coatings or alloys that resist saltwater corrosion can prevent premature failure. Balancing material cost with performance ensures reliability without unnecessary expenditure, aligning with both safety standards and budget constraints.

Lastly, assess the sealing mechanisms and actuation options to match your system's demands. Non-rising stem valves often feature advanced sealing technologies, such as resilient seats or metal-to-metal designs, which minimize leakage risks under varying temperatures and pressures. Pairing these with appropriate actuators, whether manual, pneumatic, or electric, enhances control precision and operational safety. By prioritizing these considerations, you can select valves that not only meet functional requirements but also optimize workflow efficiency, reducing downtime and maintenance costs in the long run.

Comparative Advantages of Non-Rising Stem Valves Over Traditional Valve Types

While traditional rising stem valves have long been the go-to choice in many industrial applications, non-rising stem valves offer several compelling benefits that can make a significant difference in specific settings. Unlike their traditional counterparts, these valves keep the stem stationary within the valve body, which not only reduces the overall height requirement but also minimizes the risk of stem damage or corrosion from external exposure. This design is particularly advantageous in tight or confined spaces where vertical clearance is limited, such as in underground installations or compact machinery setups.

Another key advantage lies in improved sealing and durability. With the stem not moving up and down, there's less wear on packing materials, leading to fewer leaks and a longer service life. Additionally, the non-rising stem design often allows for smoother operation, as the valve can be actuated without the stem protruding, reducing the chance of interference with surrounding equipment. This makes them a reliable option for applications requiring frequent cycles or precise flow control, such as in chemical processing or water treatment plants.

When it comes to maintenance and safety, non-rising stem valves tend to shine. Their compact form factor simplifies inspection and repair, while the enclosed stem reduces the risk of injury from moving parts. In environments where hygiene is critical, like food and beverage production, the lack of external stem movement helps prevent contamination. Overall, these valves provide a robust alternative that combines efficiency, space savings, and enhanced performance over traditional types, making them worth considering for many modern industrial needs.

Industry Applications and Real-World Use Cases for Gate Valve Technology

Gate valves are the silent workhorses of industrial settings, offering robust performance in scenarios where a straight-line flow is essential. In the oil and gas sector, for instance, these valves stand up to high-pressure environments, ensuring seamless control over crude oil pipelines and refining processes. Their full-bore design minimizes pressure drop, making them ideal for applications where every bit of efficiency counts, from offshore rigs to onshore distribution networks. When you need to stop or start flow completely without throttling, gate valves deliver, proving indispensable in emergency shutdown systems where reliability is non-negotiable.

Beyond energy, gate valves find a home in water treatment facilities, where they manage the flow of potable and wastewater with precision. In municipal systems, their ability to handle large volumes without clogging keeps cities running smoothly, from treatment plants to fire hydrant networks. For industries like mining, which deal with abrasive slurries, specialized gate valves with hardened materials prevent wear and tear, extending service life in harsh conditions. This adaptability shows how gate technology evolves to meet real-world challenges, not just as generic components but as tailored solutions that keep operations humming.

In manufacturing and chemical processing, gate valves play a critical role in safeguarding both product quality and worker safety. They isolate sections of pipelines during maintenance, preventing hazardous leaks in systems handling corrosive or toxic substances. Take a pharmaceutical plant, for example—here, sanitary gate valves ensure sterile conditions by providing a flush interior that resists contamination. Whether it's controlling steam in power generation or managing aggressive media in petrochemicals, gate valves are engineered for durability, often outlasting other valve types in demanding cycles. This makes them a go-to choice where downtime is costly and performance can't be compromised.

FAQ

Non-rising stem gate valves are often favored because they save vertical space, as the stem doesn't extend outside the valve body, making them ideal for tight or underground installations where clearance is limited.

Top manufacturers enhance durability by using robust materials like stainless steel or bronze for stems and seats, incorporating corrosion-resistant coatings, and conducting rigorous pressure and wear testing to withstand harsh operational conditions.

Yes, many modern non-rising stem valves are designed for ease of maintenance, with features such as replaceable stem packing and accessible bonnets, allowing for quick repairs without removing the entire valve from the pipeline.

Challenges include potential stem thread wear and difficulty in visual stem position indication. Companies address these by using self-lubricating materials for threads and adding external indicators or position sensors to monitor valve status accurately.

Non-rising stem valves typically require less manual effort to operate, as the stem rotates in place without moving up or down, but they may lack the tactile feedback of stem movement that rising stem valves provide, which some operators prefer for precise control.

These valves are widely used in water treatment, oil and gas, and chemical processing industries due to their space-saving design, reliability in high-pressure environments, and ability to handle a variety of fluids without leakage issues.

Recent innovations include the integration of smart monitoring systems for real-time data on valve performance, enhanced sealing technologies to reduce fugitive emissions, and modular designs that allow for easier customization and upgrades in existing systems.

Regulations drive the use of eco-friendly materials, stricter leak-prevention standards, and fail-safe mechanisms. Companies respond by developing valves with improved stem seals, fire-safe certifications, and compliance with international standards like API and ISO to ensure safe and sustainable operations.

Conclusion

Non-rising stem gate valves have emerged as a standout solution in high-demand industrial environments due to their compact design and operational efficiency. Unlike traditional valves, these models excel where space is limited, as the stem does not require upward movement during operation, making them ideal for tight installations and reducing the risk of damage from external forces. Leading companies have driven key engineering innovations, such as advanced sealing technologies and corrosion-resistant materials, which enhance durability and reliability under extreme conditions. This has positioned top manufacturers at the forefront, setting standards for robust and long-lasting solutions across sectors like oil and gas, water treatment, and chemical processing.

When selecting industrial gate valves, essential considerations include material compatibility, pressure ratings, and ease of maintenance, with non-rising stem options often offering superior performance in demanding applications. Their comparative advantages over traditional types include lower maintenance needs, reduced leakage risks, and better suitability for automated systems, as highlighted in real-world use cases. For instance, in pipeline systems or processing plants, these valves provide precise control and enhanced safety, demonstrating how expertise from leading companies shapes modern engineering practices to meet evolving industry challenges effectively.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com